This article has colaboration of Pietro Domingues.

There are many ways to make electronics fast and safely (using conductive inks, kits with magnetic contacts, breadboards, etc). However, the soldering method is still indispensable to definitive PCB assembles and to low cost solutions.

But handling the soldering iron may offer some risks to the user, mainly to children. To avoid these risks, it is recommended to use PPE (Personal protective equipment), as gloves and glasses. Even though, the metallic part of the soldering iron is too long and still offers risk of burning some part of the body.

Based on this, we developed a Silicone protector…

…that can be made following the 10 steps above:

1 – Cut a semi-rigid plastic film (such as obtained from folders, cards, packages in general, etc). The length must the same as from the metallic part of the soldering iron

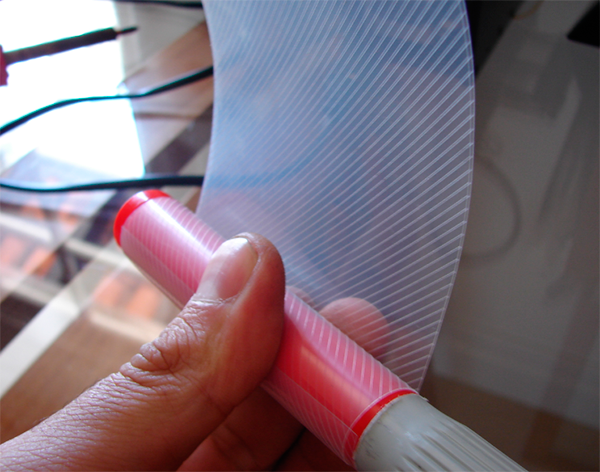

2 – Wrap the plastic film

3 – Glue the tube with adhesive tape.

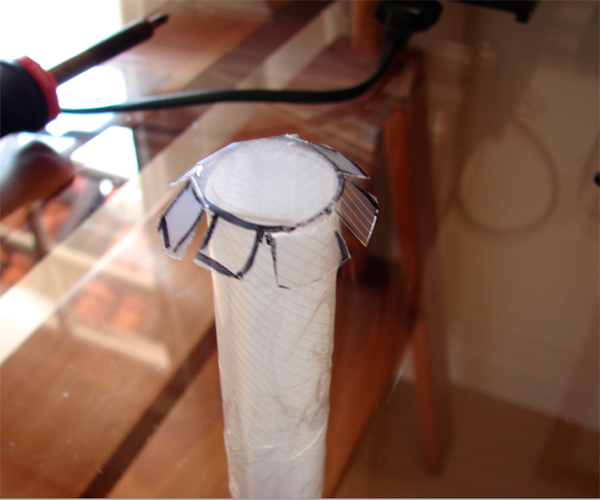

4 – Now make a lid for the tube. First, draw a circle of the same diameter of the tube on a piece of the plastic film. After this, cut the plastic film as a flower (like the image).

5 – Glue the lid on the tube.

6- This is a very important step. This tube is a mold for the Silicone, so if there exists any gap, the liquid Silicone will leak. A good solution is to wrap a thin PVC film around the tube, so it covers any possible gap.

7 – Fix the tube rigidly at vertical position. (The lid must be at the bottom)

8 – Put the Silicone in the tube. Notice that the Silicone must be suited for high temperatures (See tutorial). Fill just the half of the tube (because of the soldering iron).

9 – The Silicone still liquid, put the soldering iron inside the tube, concentric to it.

10 – Wait about six hours, and the Silicone will be solid. After checking it is solid, take the soldering iron off of the mold and cut the Silicone, exposing the tip of the soldering iron, ready to be used.

Final considerations

At the first times, the soldering iron may smell Silicone, due to the heat. It is recommended to use it at a fresh and ventilated location. Silicone is an excellent thermal insulator, but after many minutes of use the Silicone may get hot. Nevertheless, this heat is not harmful. (The unprotected soldering iron can really injury the user).