This summer we wanted to host a MakerCamp for Kids in their first week of the summer vacation. My initial idea was to run it as an open lab, but since many kids doesn´t really know what they could expect by turning up, we decided to buy a classroom kit of 6 Air:bits for building drones and gave it the theme “Game of Drones”.

The invite, translated from danish sounds something like this:

“Welcome to MakerCamp 2021. You will be working in a team of 4-5 kids, where each team gets an Air:bit drone to assemble. Your task is to improve the software, tweak the drone, create an identity for your drone. Finally your drone will compete with the other drones on a field that we create together as well. During the MakerCamp there will be introduction workshops for 3D-modelling in fusion360 and Micro:bit programming.”

My alarm bells rang different tunes:

- Would making it into a contest, be counterproductive towards the willingness to take risks in their designs?

- I´m no fan of KITS in general. You could call it DIY but it is more DIBSEHADIFY (Doing It Because Someone Else Has Already Done It For You) A term my first visit to the BETT conference in London gave birth to back in 2015.

- What about their own ideas, would there be room for messing about with other stuff?

My concerns were not met, and there were several reasons for that. One of them was that the MakerCamp took a turn on day 1 that changed the whole setup.

After having learned a bit about each other – most of them didn´t know each other beforehand – we made our first modelling in fusion360. Next step was to create teams, unpack the Air:bit kits and get to work. But, when I open the box, there were no Drone kits in it. My boss had accidentially ordered a classroom set of Hover:bits instead! Uh-oh was my first thought, but then again, the controller board was the same and the motors were almost complete in terms of having two clockwise and two counterclockwise motors for each drone – I had ordered a few spare motors prior to the Camp, which was just about enough. But everything else we suddenly had to make on our own. It was a little crisis! And a crisis gives birth to authentic problems that needs to be solved.

What happened was that the kids went head on in getting the missing parts made in the lab. The air was filled with determination and urgency in getting the job done. The newly achieved 3D-modelling skill went into making the spacers needed for the drone to be set a bit above ground. The body of the drone was lasercut. We used the base that is provided as a resource from the Air:bit website, but they also made personal tweaks to it. Though the day took a turn and a lot of extra time was needed for covering the basic parts of the drone, it was a much more interesting as it would have been otherwise.

Finding screws from scrap materials

Screws from the Guitar Hero controller was scrapped for mounting the spacers

3D-printed spacer – and the screws fit!

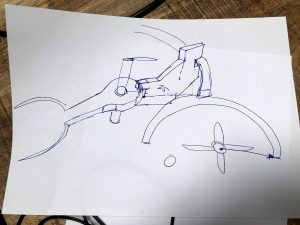

Designing protectors for the propellers

Drawing it out

Designing protectors for the propellers

The race field version 1. It was made a bit more simply in the end

On the hunt for a neodymium magnet to make the drone pick up metal

The lesson here could be – buy the wrong kit or use kits another way than they were intended. On a more serious note I would say, just buy the controllerboard, battery, some motors and make the rest yourself.

As for the concerns on having a competitive setting. The students were more engaged into making it fly and redesigning it to fly better, than in winning the race. Let me share the story of one of the most daring design, build by the brilliant student Mikkel.

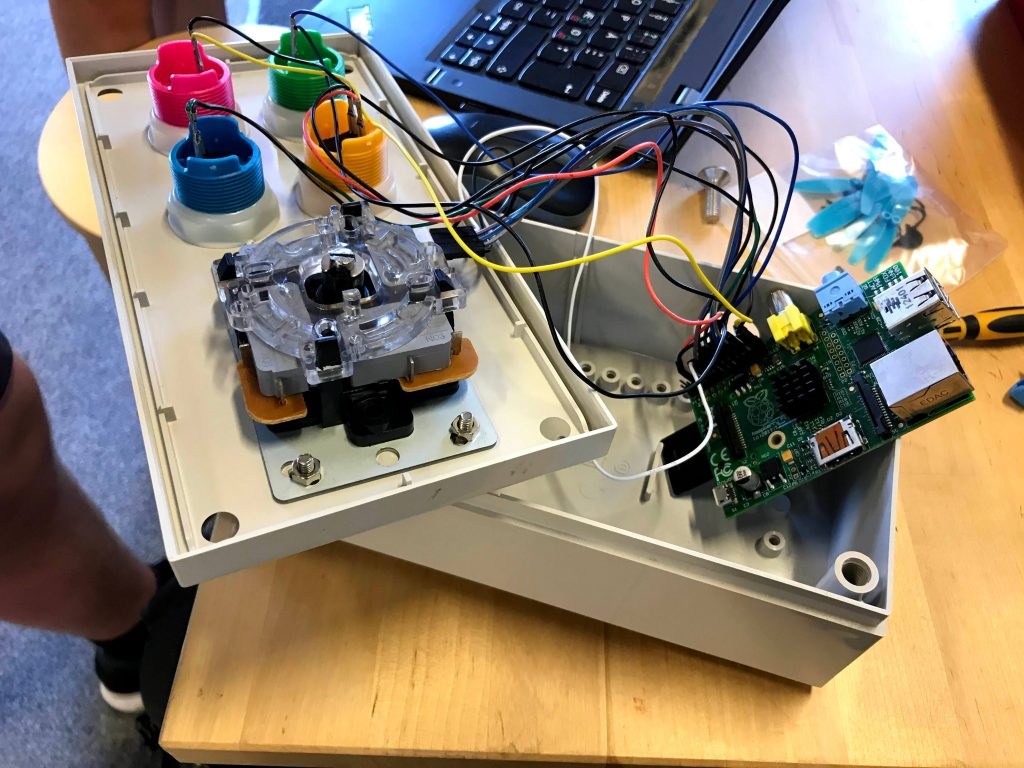

On the first day he found a prototype I had build for an arcade machine – an analog joystick and a few buttons. He wanted to use that as the controller. He ended taking it home with him and worked the whole evening. He continued working through day 2 and succeeded in having it working smoothly on the final day. But he was the only one able to fly it properly, the rest of his team had focused on the drone body, protectors, stabilizers etc.

First heat of the race went well and they had a lot of points. One of his team mates, actually the one who by far contributed the least to the project – doing all sorts of other stuff – asked if he could fly the second heat, and Mikkel handed him the controller just like that – go ahead he said. He had no experience with that controller and it was a disaster, but no one was angry with him. In fact Mikkel had already won, his own game anyway. He had make it work the way he imagined, and succeeded!

Redesigning an arcade controller to fly a drone. A Raspberry Pi connected to a micro:bit.

I will be doing this workshop again this summer but the next time I will frame it as “make something move”. It could be a drone, hovercraft, boat, car or maybe something completely different. And I think I will let it be up to them if want to make a race.

Embrace the mistakes you make and allow it to take you in an unexpected direction. Lesson learned.

Flot arbejde med ungerne Lars! Bare det var mig.